Views: 0 Author: Site Editor Publish Time: 2025-09-01 Origin: Site

Your car wiring harness helps keep your car safe. It also helps your car run well. You may see common faults like circuit overload or poor connections. Other problems are wire fractures, water getting in, or wires wearing out. Here is a quick table:

| Fault Type | Description |

|---|---|

| Circuit Overload | Too much current makes wires too hot. |

| Poor Connections | Loose connectors can cause heat and fire. |

| Wire Harness Fractures | Stress or bad assembly can break wires near moving parts. |

| Water Ingress | Water causes rust and electrical problems. |

| Wear and Tear | Old wires break easily, especially in hard conditions. |

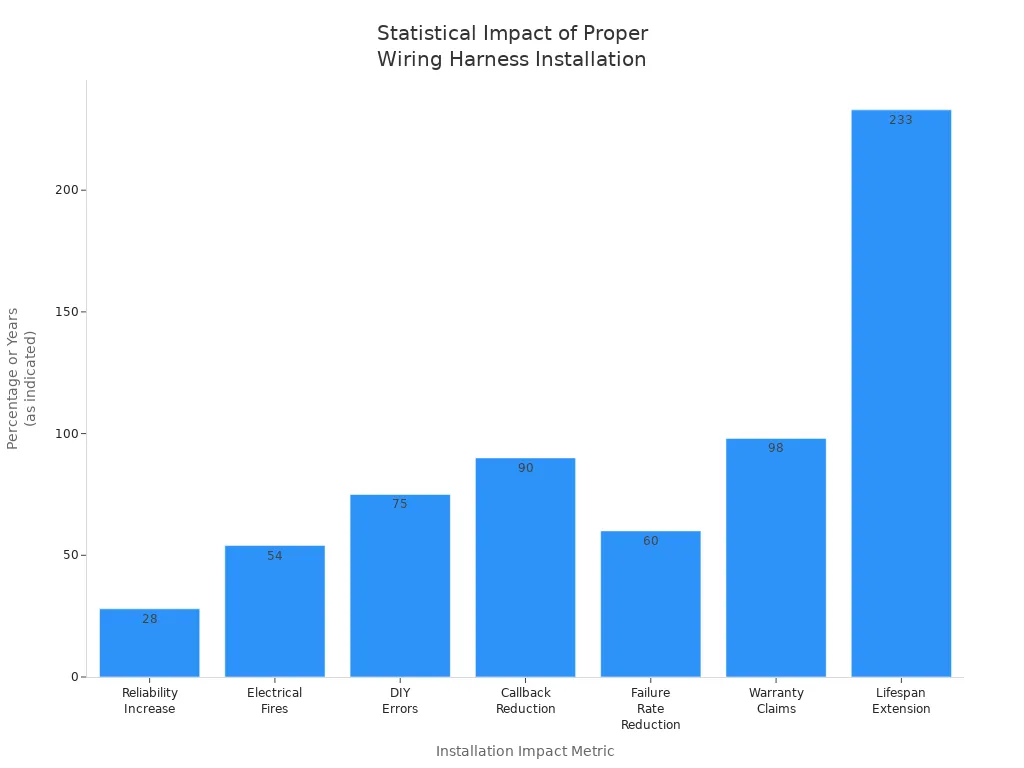

Installing an automotive wiring harness the right way matters a lot. The right steps make your car much more reliable. Look at how reliability goes up with good installation:

You can stop most problems by using simple checks. You should also install new harnesses the right way.

Check your car's wiring harness often for cracks, frays, or rust. Finding problems early can stop bigger ones and helps your car work well.

Make sure all connections are clean and tight. Put dielectric grease on connectors to keep out water and dirt. Water and dirt can cause electrical problems.

Pick wiring harnesses that resist heat and water. This makes your harness last longer and stops damage from weather.

Use a step-by-step guide when you put in a wiring harness. Doing it right lowers the chance of problems and makes your car more reliable.

Watch for warning signs like lights that flicker or burning smells. Fixing these problems fast can help you avoid expensive repairs.

When you open the hood, you see lots of wires. These wires are part of your car wiring harness. If something goes wrong, your car may not work right. Sometimes, it might even stop working. Let’s look at the most common faults you can find.

Broken wires are a big problem for car owners. You may see your lights blink or your radio turn off. Sometimes, your car will not start. Wires break for a few reasons:

Mechanical stress, like shaking, can wear out insulation and snap wires.

Electrical shorts can happen if insulation breaks or water gets in, letting electricity go the wrong way.

Open circuits show up when wires break or connectors get loose.

Connector problems, like rusty contacts or bad crimping, can stop power from flowing.

Manufacturing defects, such as poor design or weak materials, make wires easy to break.

You can find broken wires by looking for frayed ends or exposed copper. Wires that feel loose when you pull them are also a sign. If you see these things, you should fix or replace that part of your car wiring harness.

Tip: Always check for broken wires near moving parts, like doors or the engine. These places get the most stress.

Corrosion is like rust but sneaky. It gets into connectors and slowly eats the metal. When connectors corrode, they do not carry electricity well. You may see warning lights on your dashboard or notice things like power windows stop working.

Water is the main cause. It can get in through small cracks or worn seals. Once inside, it reacts with metal and makes a green or white crust. This crust blocks electricity. If you see green or white powder on connectors, it is probably corrosion.

To stop this, keep connectors dry and clean. Use dielectric grease to protect them from water. If you find a corroded connector, clean it with a wire brush or replace it if it is too damaged.

Loose connections can cause many strange problems. Your headlights may blink. Sometimes, your car will not start or you hear clicking when you turn the key. Loose connections happen when connectors are not plugged in all the way or terminals do not fit tight.

You may find loose connections after a bumpy ride or if someone worked on your car and did not snap everything back. Even small gaps matter. Electricity needs a solid path to flow. If the connection is loose, you get heat, sparks, or even fire.

Check all connectors and terminals when you look at your car wiring harness. Push them in hard and listen for a click. If a connector feels loose or falls out, replace it.

Note: Loose connections can drain your battery over time. Always check after any repair.

Short circuits are very dangerous faults in a car wiring harness. A short circuit happens when electricity takes a shortcut and skips the normal path. This can make wires too hot, blow fuses, or start a fire.

A short circuit can happen if two wires touch or if insulation breaks. Sometimes, water gets inside and lets electricity jump. You may see blown fuses, melted wires, or smell burning.

Many parts can cause short circuits, including:

Battery plugs

Wiring harnesses

Fuse boxes

Plug wires

Connectors

Switches

Terminals

Defective plugs

Broken insulation

Engine wiring

Spark plugs

Coil packs

If you think there is a short circuit, look for melted insulation, black connectors, or blown fuses. Fixing a short circuit fast can save your car from bigger problems.

Burned insulation means something got too hot. You may see black wires, smell burning plastic, or see melted spots on the harness. Burned insulation can cause shorts, open circuits, or fires.

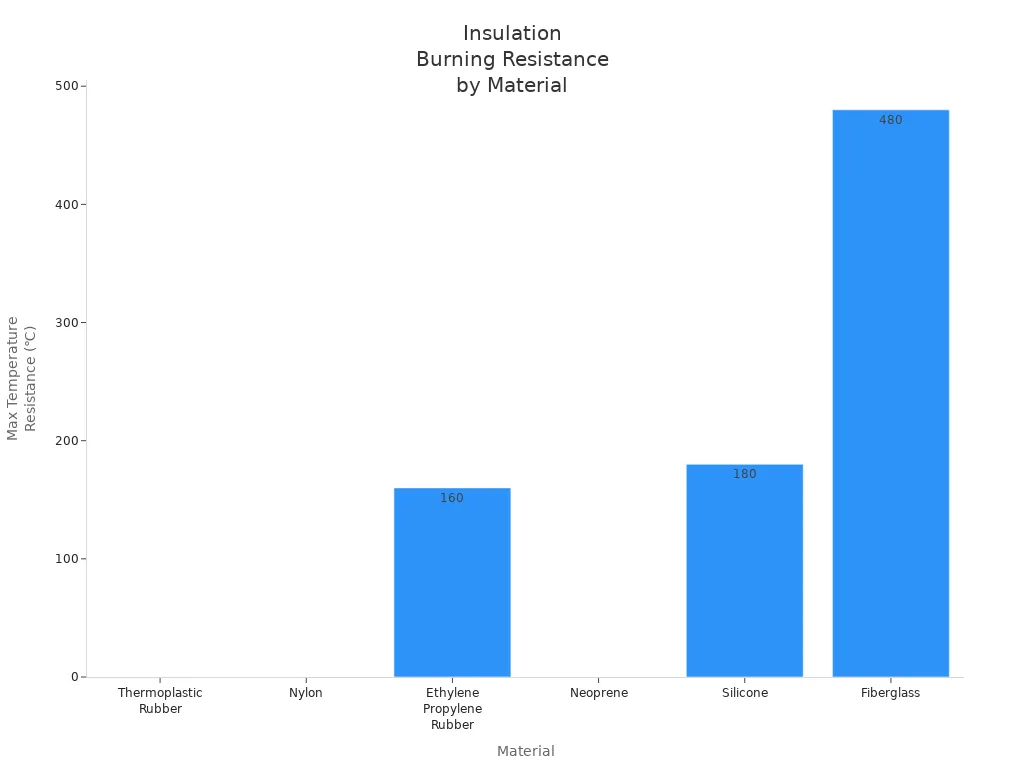

Some insulation materials handle heat better than others. Here is a quick look at which ones work best:

| Material | Temperature Resistance | Chemical Resistance | Other Properties |

|---|---|---|---|

| Thermoplastic Rubber | High temperatures | UV radiation | Tough blend, weather resistant |

| Nylon | Moderate to high | Excellent | Flexible, abrasion resistant |

| Ethylene Propylene Rubber | -50℃ to 160℃ | Excellent | Superior thermal properties |

| Neoprene | Moderate | Superior | Better electrical conductivity |

| Silicone | Up to 180℃ | Excellent | High flexibility, flame retardant |

| Fiberglass | Up to 480℃ | Excellent | High temperature and chemical resistance |

If you want your car wiring harness to last, pick wires with good insulation. Silicone and fiberglass protect best against heat and chemicals. Always replace burned wires right away to keep your car safe.

Alert: Burned insulation can hide bigger problems. If you see it, check the whole harness for damage.

A car wiring harness is the backbone of your car’s electrical system. If you know what to look for, you can find problems early and keep your car running well.

You can spot many Car Wiring Harness problems just by looking closely. Start with a simple check. Look at the wires and connectors under your hood. You want to see clean, bright colors. If you notice faded or mismatched wire colors, that’s a sign something’s wrong. Check the thickness of each wire. Thin or uneven wires might break soon.

Take a moment to measure the length of each cable. Short or stretched wires can pull loose. Make sure IDC cables sit straight and fit snugly. Dirty contacts or connectors can block electricity. Wipe away any dust or grease. Look for broken strands or frayed ends. If you see any, you should fix them right away.

Tip: Always inspect wires for cracks or cuts. Even a small break can cause big trouble in your Car Wiring Harness.

Your Car Wiring Harness can show problems through strange electrical behavior. You might notice your engine acting up. Sometimes, the motor runs rough or makes odd noises. Sudden changes in speed, like jerking or stuttering, can mean a wiring fault. If your car speeds up or slows down without warning, check the harness.

Gadgets in your car may stop working. The radio might cut out, or the dashboard lights flicker. If you see the check engine light, don’t ignore it. This light often means the wiring harness is not sending signals right. Data loss during transmission can make electronics act weird.

Engine runs rough or makes strange sounds

Car jerks, stutters, or lurches

Dashboard lights flicker or gadgets fail

Check engine light turns on

You can catch Car Wiring Harness faults early if you know what to look for. Watch for warning signs every time you drive. Burning smells or melted plastic mean wires got too hot. If you hear clicking when you turn the key, that’s a clue. Loose connectors can drain your battery and cause starting problems.

Look for water near connectors. Moisture can lead to rust and corrosion. If you see green or white powder, clean it off. Wires that feel soft or sticky may have damaged insulation. Always check after repairs or bumpy rides.

Alert: Never ignore warning signs. Small problems in your Car Wiring Harness can grow fast and cost you more later.

Ready to install a wiring harness in your car? This step-by-step installation guide will walk you through each part of the process. You’ll learn how to avoid common mistakes and make sure your wiring harness installation is safe and reliable. Let’s get started!

Preparation and safety come first. Before you touch any wires, you need to get your tools and materials needed. Here’s what you should do:

Disconnect the battery. Always start by disconnecting the battery. This keeps you safe from shocks and prevents short circuits.

Gather your tools and materials needed. You’ll want wire cutters, crimpers, screwdrivers, a multimeter, zip ties, heat shrink tubing, and your new wiring harness kit.

Study your car’s wiring diagram. Look at your vehicle’s manual or wiring diagram. This helps you plan the harness route and see where each wire goes.

Plan the harness route. Think about where the wires will run. Avoid sharp edges and hot spots. Lay out the old harness on a workbench if you’re replacing it. This gives you a good reference for length and routing.

Wear safety gear. Put on safety glasses and insulated gloves. Make sure your work area is dry and clean.

Label the terminals. Use masking tape or labels to mark each terminal. This makes it easier to connect everything later.

Tip: Take photos of your old wiring before you remove it. These pictures help you remember where each wire goes.

Now it’s time to remove the existing harness. This step is important for a clean installation.

Start by unplugging all connectors from the old harness. Work slowly and gently to avoid breaking clips.

Remove any zip ties or clamps that hold the harness in place.

Carefully pull the old harness out of the car. Watch for wires that might be stuck or tangled.

Check for any damaged connectors or wires. If you find any, make a note so you can fix them during the new installation.

If you use a wiring harness kit from TSCN Connector, you’ll notice that their connectors have easy-release tabs. This makes it simple to unplug old connections without damaging the terminals.

Alert: Don’t yank on the wires. Pulling too hard can break connectors or damage other parts.

Next, lay out the new harness. This step helps you see if everything fits before you start connecting wires.

Spread the new harness on a clean surface. Compare it to the old harness if you have one.

Check that all connectors and wires match the locations in your car.

Plan the harness route again. Make sure wires will not rub against sharp edges or hot engine parts.

Bundle and secure the harness with zip ties or tape. This keeps wires neat and prevents tangling.

TSCN Connector’s car wiring harness products use flexible, high-quality insulation. This makes it easy to route wires through tight spaces. Their harnesses also come with pre-installed clips and labels, which help you bundle and secure the harness quickly.

Tip: Leave a little extra slack in the wires. This helps prevent strain when the car moves or vibrates.

Now you’re ready to connect power wires and secure everything in place. Follow these steps for a safe and strong connection:

Cut wires to the right length. Remove just enough insulation to expose the copper core.

Use the correct crimping tool to attach terminals. Make sure each crimp is tight and secure.

Slide heat shrink tubing over each connection. Use a heat gun to shrink it for a tight seal.

Insert terminals into the connector housing. Listen for a click to know they’re locked in.

Secure the harness to the car body with zip ties, clamps, or mounting points. Avoid loose wires that could move or rub.

Bundle and secure the harness along the planned route. Double-check that nothing is pinched or stretched.

Here’s a quick table of best practices for wiring harness installation:

| Best Practice | Description |

|---|---|

| Proper Wire Preparation | Cut wires to the right length and remove insulation carefully to expose the conductive core. |

| Correct Crimping Procedures | Use the appropriate tools to attach terminals securely without damaging the wire or terminal. |

| Insulation and Strain Relief | Apply heat shrink tubing over connections to protect and relieve strain, ensuring a tight seal. |

| Secure Connector Housing | Insert terminals correctly into the housing and secure with locking mechanisms to prevent disconnection. |

TSCN Connector harness kits include color-coded wires and labeled connectors. This makes it easy to connect power wires and avoid mistakes. Their secure locking connectors help prevent loose connections, which are a common cause of electrical faults.

Note: Always follow the instructions that come with your wiring harness kit. Each kit may have special steps for your car model.

You’re almost done! The last step is to test the installation and make sure everything works.

Reconnect the battery. Be careful and check for any sparks or strange smells.

Test the installation by turning on the ignition. Check all lights, switches, and accessories.

Use a multimeter to check for voltage at key points. Make sure every circuit works as it should.

Look for warning lights on the dashboard. If you see any, double-check your connections.

Take a few photos of your finished work. These can help you or a mechanic in the future.

Double-check that all wires are secure and not touching hot or moving parts.

TSCN Connector harnesses are designed for easy testing. Their connectors fit snugly, so you get a reliable connection every time. If you need to troubleshoot, their labeled wires make it simple to find the problem fast.

Alert: Never skip the final checks. Testing now can save you from bigger problems later.

By following this step-by-step installation guide, you can install a wiring harness with confidence. Good preparation and safety habits help you avoid common faults. When you bundle and secure the harness, you protect your car’s electrical system for years to come. Always test the installation before you hit the road.

You can stop most Car Wiring Harness problems before they start by checking your wiring often. When you look at your harness, you might spot cracks, frays, or worn spots on the insulation. These small issues can turn into big problems if you ignore them. Loose or corroded connectors show up early during a quick check. You may also notice signs of water getting in, like moisture or rust, before they cause real trouble.

Look for cracks, frays, or abrasions on the insulation.

Check connectors for looseness or corrosion.

Watch for any signs of moisture or rust.

Ask a professional to inspect your Car Wiring Harness during regular maintenance.

Regular inspections help you catch problems early. This keeps your car running well and can make your Car Wiring Harness last longer. You also get better performance and fewer electrical issues.

Tip: Make it a habit to check your Car Wiring Harness every time you change your oil or visit your mechanic.

Dirty or loose connections can cause your Car Wiring Harness to fail. You should clean your connectors often to keep them working right. Use a soft, dry cloth and a safe cleaning spray to wipe away dirt. Make sure everything is dry before you put it back together. If you see dust or dirt in tight spots, use a little compressed air to blow it out.

Clean connectors with a soft cloth and safe cleaner.

Dry all parts before reconnecting.

Use compressed air for hard-to-reach places.

Check that every connector snaps in tight.

When you keep your Car Wiring Harness clean and secure, you lower the risk of electrical failures. Regular cleaning also stops corrosion and keeps your car’s electronics working smoothly.

Note: Cleaning and securing your Car Wiring Harness only takes a few minutes but can save you from big repair bills.

Heat and water are the biggest enemies of your Car Wiring Harness. You can protect your harness by choosing the right materials and using extra shields. Wires made from PVC, TPU, Teflon, or silicone resist heat and moisture. You can also use sleeves or covers to keep water out. Sealing connectors and using heat-shrink tubing adds another layer of safety.

Pick harnesses with heat- and moisture-resistant materials.

Add protective sleeves or covers.

Seal connectors and terminals to block water.

Use heat-shrink tubing for extra protection.

When you protect your Car Wiring Harness from heat and moisture, you help it last longer and work better. TSCN Connector offers harnesses with strong insulation and sealed connectors, so you get the best protection for your car.

Alert: Never ignore signs of heat or water damage. Fix them fast to keep your Car Wiring Harness safe and reliable.

Taking care of your Car Wiring Harness pays off in the long run. When you install it right and check it often, you avoid most common faults. You also get these benefits:

You see fewer short circuits because the wires stay organized.

You find setup easier, so mistakes happen less.

Your car runs better and uses less fuel.

The harness lasts longer, even in tough weather.

Stick to the step-by-step guide and check your wiring often. If you spot a problem or feel unsure, reach out to a pro. Your car will thank you!

A Car Wiring Harness connects all the electrical parts in your car. You get power to lights, radio, and sensors. It keeps wires organized and safe. If you want your car to run smoothly, you need a good harness.

You might see flickering lights, hear odd sounds, or smell burning plastic. Sometimes, your car won’t start. Check for broken wires, loose connectors, or signs of corrosion. If you spot these, your Car Wiring Harness needs attention.

Yes, you can! If you follow a step-by-step guide and use the right tools, you can install a Car Wiring Harness at home. Always disconnect the battery first. Take photos before you start. If you feel unsure, ask a pro for help.

TSCN Connector offers harnesses with strong insulation, labeled wires, and secure connectors. You get easy installation and reliable performance. Their products resist heat and moisture, so your Car Wiring Harness lasts longer and keeps your car safe.

You should check your Car Wiring Harness every time you change your oil or visit your mechanic. Regular inspections help you catch problems early. Clean and secure connections keep your car’s electrical system working well.